Hotel managers waste thousands of dollars on the wrong linens. They buy home-grade products that fall apart after 50 washes. We’ve seen this mistake destroy budgets and guest satisfaction scores.

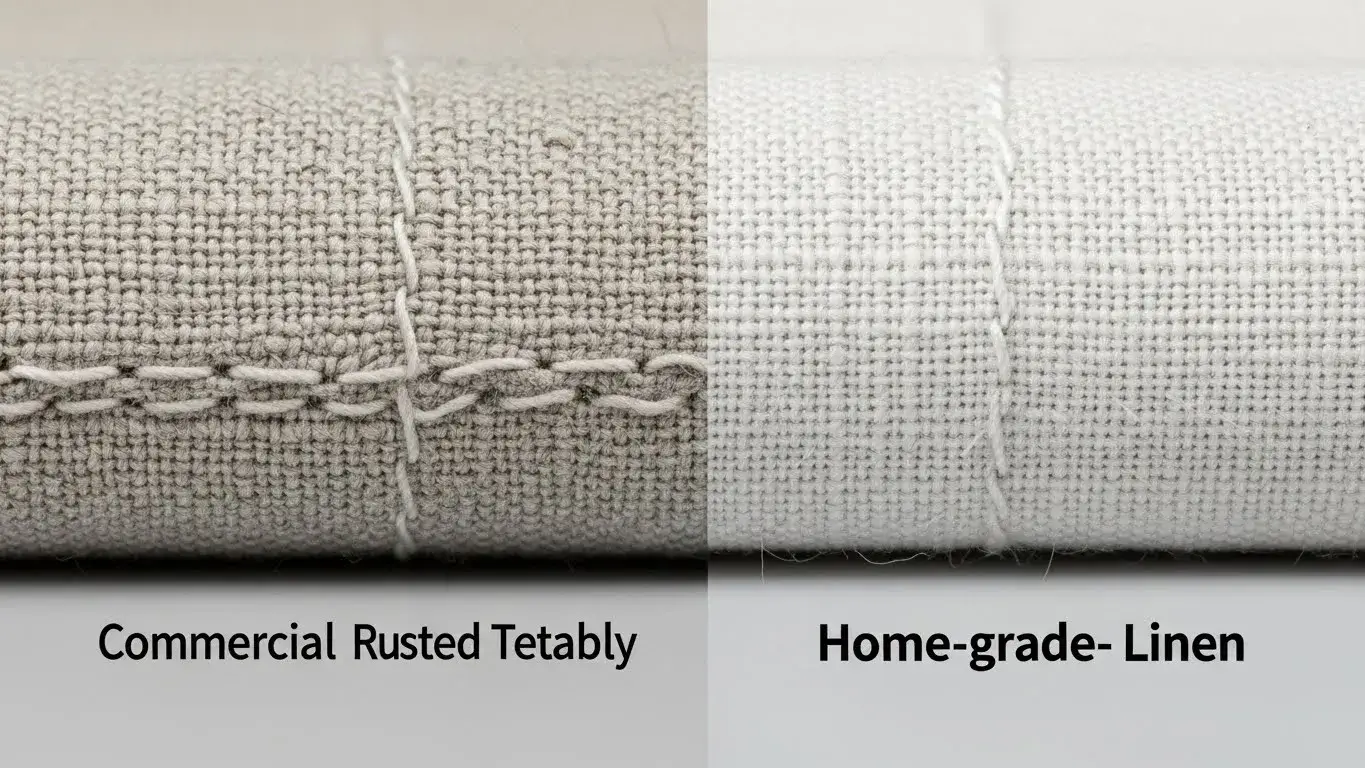

Commercial linens are heavy-duty textiles designed for high-frequency use in hotels and hospitals, built to withstand 200-500 industrial washes. Home linens prioritize comfort and aesthetics for personal use, lasting 50-100 washes. The key differences lie in material weight (155-180g vs. lighter fabrics), construction methods, and durability standards.

Understanding these differences helps you make smarter purchasing decisions. Let me walk you through everything we’ve learned from supplying linens to hotels worldwide.

What Are Commercial and Home Linens?

We often get calls from new hotel owners confused about linen types. They see "hotel-quality" labels at retail stores and wonder if they’re getting the same product. They’re not.

Commercial linens are textiles manufactured for hospitality, healthcare, and institutional settings where durability matters most. Home linens are designed for residential use with emphasis on softness and decorative appeal. Commercial versions use reinforced stitching and heavier fabrics to survive industrial laundering cycles.

The Basic Definition Breakdown

Let me clarify what we mean by each category.

Commercial linens include sheets, towels, pillowcases, and duvet covers built for hotels, hospitals, spas, and restaurants. We manufacture them with specific weight requirements. Most commercial sheets weigh between 155-180 grams per square meter1. This extra weight prevents tearing in industrial dryers.

Home linens are what you find at department stores. They come in hundreds of colors and patterns. Manufacturers focus on thread count marketing rather than wash durability. A typical home sheet might boast 400+ thread count but uses thinner yarns.

Key Construction Differences:

| Feature | Commercial Linens | Home Linens |

|---|---|---|

| Fabric Weight | 155-180 GSM | 90-130 GSM |

| Primary Material | Polycotton blends (60/40) | 100% cotton or mixed |

| Stitching | Reinforced edges, double-stitched hems | Standard stitching |

| Color Options | Limited (mostly white) | Extensive variety |

| Design Focus | Functionality | Aesthetics |

Why We Use White in Commercial Settings

You’ll notice most hotel linens are white. This isn’t just tradition. White linens allow us to use bleach for deep sanitization. We can spot stains immediately during sorting. This matters for infection control in healthcare settings.

Home buyers want colors that match their bedroom decor. Commercial buyers need consistency across 200 rooms. We can’t have mismatched shades after multiple wash cycles.

Material Composition Matters More Than You Think

I’ve tested hundreds of fabric blends over my career. Pure cotton feels luxurious but shrinks unpredictably. Commercial operations can’t afford sheets that no longer fit mattresses after 20 washes.

We use 60% cotton and 40% polyester2 in most commercial products. The cotton provides breathability. The polyester adds strength and wrinkle resistance. This blend maintains its shape through hundreds of industrial wash cycles.

Home linens often use 100% cotton because customers touch the fabric in stores. They feel the softness and buy based on that initial impression. They don’t think about how it performs after 50 washes.

How Durable Are Commercial Linens Compared to Home Options?

We test our linens to destruction. Literally. We have machines that simulate years of use in weeks. The results always show the same pattern.

Commercial linens survive 200-500 industrial wash cycles before showing significant wear. Home linens typically last 50-100 home washing cycles. This 4-5x durability difference comes from heavier fabric weights, reinforced stitching, and industrial-grade fiber blends designed specifically for commercial laundry systems.

The Real Cost of Durability

Let me break down what this durability means for your budget.

A commercial sheet costs about $15-25 at wholesale prices. It lasts 300 washes. That’s roughly $0.05-0.08 per use. A home sheet costs $30-50 retail but only survives 75 washes. That’s $0.40-0.67 per use.

The math is clear. We see hotel managers make this mistake constantly. They buy retail linens trying to save money upfront. Six months later they’re replacing everything.

Understanding Wash Cycle Differences

Commercial laundering is brutal compared to home washing. We use:

- Water temperatures up to 160°F (71°C)3

- Heavy-duty detergents with higher pH levels

- Industrial extractors spinning at 1000+ RPM

- Tunnel washers that process 1,000+ pounds per hour

Your home washer runs maybe 600-800 RPM. The detergent is gentle. The water is lukewarm. Commercial linens are built for an entirely different environment.

Maintenance Requirements Shape Longevity

I tell every new client this: maintenance matters as much as initial quality.

Commercial Linen Maintenance:

- Professional laundering required for warranty coverage

- Sorted by soil level (light, medium, heavy)

- Chemical sanitization to meet health codes

- Industrial pressing for crisp appearance

- Rotation systems to equalize wear

Home Linen Maintenance:

- Machine washable in standard washers

- Gentle detergents recommended

- Tumble dry on medium heat

- Optional ironing for appearance

- No formal rotation needed

Hotels need rotation systems. We recommend having 3-4 sets per bed. One set on the bed, one in the laundry, one in storage, one as backup. This rotation extends total lifespan by distributing wear evenly.

Home users rarely need this complexity. You wash your sheets weekly and put them back on the same bed.

What Materials Work Best for Each Setting?

We’ve sourced textiles from 12 countries over the past decade. Each material serves specific needs. Let me explain what works where.

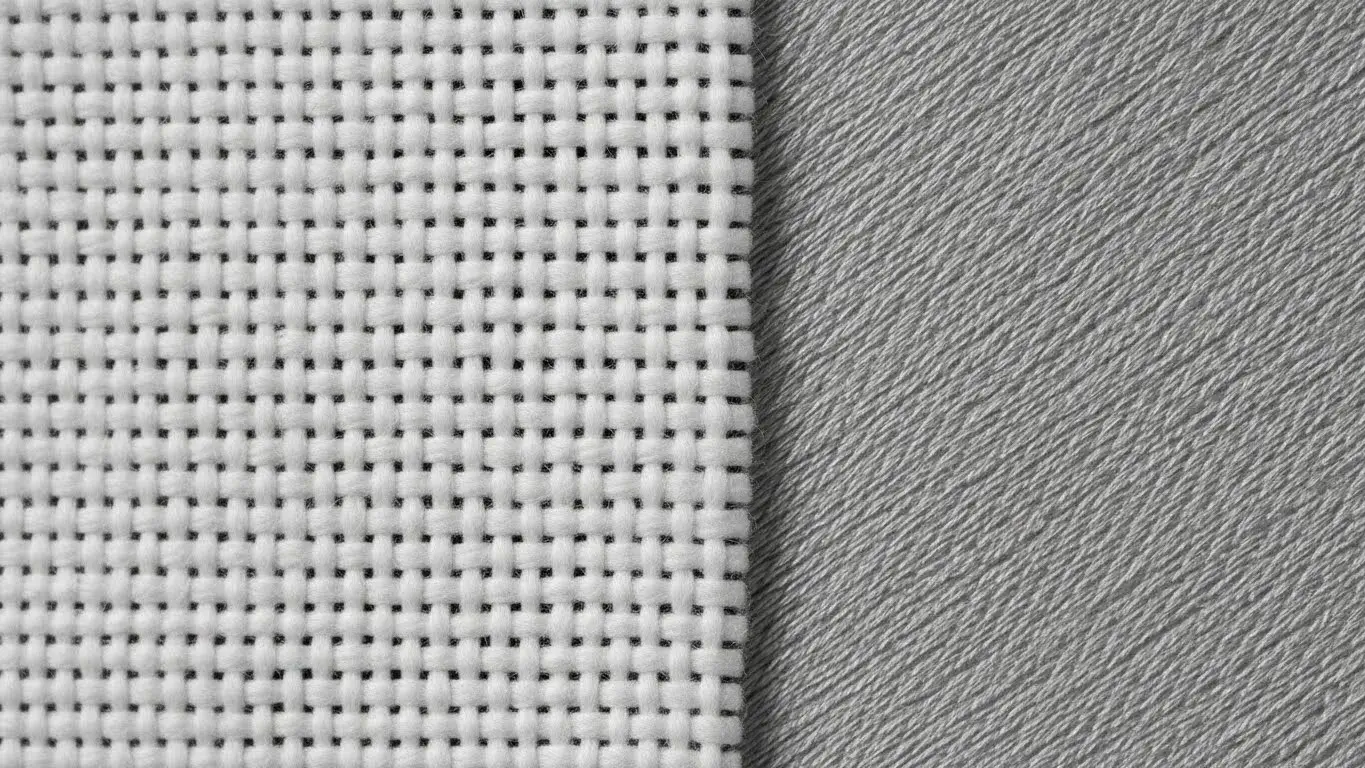

Commercial linens primarily use polycotton blends (60/40 or 50/50 cotton-polyester) with tighter weaves and heavier weights. Home linens favor 100% cotton, Egyptian cotton, or bamboo blends with higher thread counts. The material choice reflects different priorities: commercial emphasizes durability and ease of care while home prioritizes initial softness and luxury feel.

Breaking Down Commercial Material Choices

Polycotton remains our top seller for good reasons.

The 60/40 blend (60% cotton, 40% polyester) offers the best balance. Cotton provides natural breathability that guests appreciate. Polyester prevents shrinkage and adds tear resistance. This combination survives industrial washing without losing dimensional stability.

Some hotels request 50/50 blends for budget properties. The extra polyester reduces costs by 15-20%. The trade-off is slightly less breathability. For three-star properties, this makes sense. Luxury properties should stick with 60/40 or higher cotton content.

Popular Commercial Fabric Options:

- Polycotton Percale – Crisp, cool, matte finish

- Polycotton Sateen – Smoother, slight sheen, softer drape

- 100% Cotton (for luxury tier) – Premium feel, requires careful laundering

- Microfiber – Budget option, less breathable

Why Home Linens Use Different Materials

Home buyers shop with their hands. They touch fabrics in stores and judge quality by immediate softness. This drives manufacturers toward materials that feel good initially.

Egyptian cotton has become a marketing term. True Egyptian cotton uses long-staple fibers. These create softer, smoother fabrics. But they’re also more delicate. I wouldn’t put them in a commercial operation.

Bamboo linens have gained popularity for home use. They’re naturally antimicrobial and eco-friendly. However, they pill quickly under commercial laundering stress. We tested bamboo sheets for hotels and saw visible pilling after 30 washes.

Thread Count Myths I Need to Bust

Everyone asks about thread count. The hospitality industry has moved beyond this metric.

Thread count measures threads per square inch4. Home linens advertise 400-1000 thread counts. Here’s the secret: manufacturers can inflate this number by using multi-ply yarns or counting warp and weft threads multiple times.

We focus on GSM (grams per square meter) instead. A quality commercial sheet weighs 155-180 GSM. This measurement can’t be manipulated. It directly correlates to durability.

High thread count doesn’t mean durability. I’ve tested 800-thread-count sheets that failed after 40 commercial washes. Our 200-thread-count commercial sheets with proper weave construction lasted 350+ cycles.

When Should You Choose Commercial Linens for Home Use?

I get asked this question at every trade show. Homeowners want commercial durability without sacrificing comfort. It’s possible with the right approach.

Choose commercial linens for home use when you have high-traffic households (multiple children, pets, or frequent guests), operate short-term rentals like Airbnb, or prioritize long-term value over initial softness. Commercial towels particularly make sense for family bathrooms where durability matters more than luxury feel.

The Airbnb Revolution Changed Everything

Short-term rental hosts discovered commercial linens5 about five years ago. The economics made perfect sense for them.

An Airbnb property might have 200 guest nights per year. That means 200 bed changes. Home linens couldn’t handle this volume. Hosts were replacing sheets every three months.

Commercial linens solved their problem. One set lasts multiple years even with this heavy use. The initial roughness matters less because guests only sleep on them for a few nights.

Hybrid Approaches That Work

We’ve developed strategies for homeowners who want both durability and comfort.

Smart Hybrid Approach:

- Sheets: Use quality home linens (they don’t wear as quickly)

- Towels: Switch to commercial grade (towels take more abuse)

- Duvet covers: Commercial for durability, quality home duvet insert

- Pillowcases: Home linens (changed frequently anyway)

This gives you commercial benefits where they matter most. You keep comfort where you directly touch the fabric against your skin.

Breaking In Commercial Linens

New commercial linens feel stiff. This turns off home buyers. But there’s a solution.

Wash commercial linens 3-5 times before judging them. Use fabric softener during these initial washes. The softness improves dramatically after the manufacturing finishes wash out.

We tell customers: "Judge them after 10 washes, not the first night." Commercial linens actually get softer with use while maintaining their structure. Home linens feel great initially but degrade steadily.

Cost Analysis for Home Buyers

Let me show you real numbers from our customer data.

A bedroom needs:

- 2-3 sheet sets

- 4 pillowcases

- 1 duvet cover

- Replacement every 2-3 years

Home Linen Costs (5-year total):

- Initial purchase: $400-600

- Replacements (2x): $800-1,200

- Total: $1,200-1,800

Commercial Linen Costs (5-year total):

- Initial purchase: $300-450

- Replacements: $0-150

- Total: $300-600

You save $600-1,200 over five years. That’s significant for most households.

How Do Costs Compare Between Commercial and Home Linens?

Budget questions dominate every buyer conversation. Everyone wants the best value. Let me explain the real cost picture.

Commercial linens cost 20-40% less per unit when purchased wholesale but require minimum order quantities (usually 50-100 pieces). Home linens sold retail carry higher markup but allow single-piece purchases. The true cost difference appears over time: commercial linens deliver 4-5x more washes per dollar spent, making them more economical for bulk buyers despite similar or higher upfront costs.

Understanding Wholesale vs Retail Pricing

Retail stores need profit margins. They typically mark up products 100-300% from wholesale cost.

A sheet set that costs us $15 to manufacture sells wholesale at $20-25. That same product appears in retail stores at $60-100. The fabric is identical. You’re paying for retail overhead, returns, and profit margins.

Commercial buyers access wholesale pricing. But there’s a catch: minimum order requirements.

Typical Wholesale Minimums:

- Small suppliers: 50 pieces minimum

- Large suppliers: 100-500 pieces minimum

- Factory direct: 1,000+ pieces minimum

- Distributor mixed orders: Sometimes 25 pieces

Calculating True Cost Per Use

Smart buyers think beyond sticker price. Let me show you the calculation that matters.

Formula: Total Cost ÷ Expected Washes = Cost Per Use

Commercial Sheet Example:

- Purchase price: $22

- Expected washes: 300

- Cost per use: $0.073

Home Sheet Example:

- Purchase price: $45

- Expected washes: 75

- Cost per use: $0.60

The commercial sheet delivers over 8x better value. This gap widens in commercial operations with professional laundering.

Hidden Costs Most Buyers Miss

I need to address costs beyond the purchase price.

Commercial Operations Face:

- Professional laundering fees ($0.50-1.50 per pound)

- Storage space for inventory rotation

- Initial capital for bulk orders

- Replacement inventory maintenance

Home Buyers Face:

- More frequent replacements

- Higher per-unit retail prices

- Utility costs for home washing

- Time investment for laundry

Neither option is truly "cheaper." The right choice depends on your usage volume and context.

Volume Discounts and Negotiation

We offer tiered pricing based on order size. Most suppliers work similarly.

Our Typical Discount Structure:

- 50-99 pieces: List price

- 100-249 pieces: 10% discount

- 250-499 pieces: 18% discount

- 500+ pieces: 25% discount

- 1,000+ pieces: 30-35% discount

Hotels opening multiple properties can negotiate even better rates. We’ve structured deals at 40% off list price for consistent volume commitments.

Home buyers rarely get these discounts. Even buying 10 sets doesn’t qualify for wholesale treatment.

What About Comfort and Aesthetic Differences?

Comfort drives guest satisfaction scores. Aesthetics influence booking decisions. Both matter more than procurement teams often realize.

Commercial linens prioritize consistency and practicality over luxury feel, typically using white or neutral colors with minimal patterns. Home linens emphasize initial softness, decorative designs, and color variety. Commercial products feel crisper and more structured while home linens offer plush softness, though this softness diminishes faster with repeated washing.

The Tactile Experience Explained

Touch matters enormously in hospitality. Guests judge room quality within seconds of touching the bed.

Commercial percale weaves create a crisp, cool feeling6. Think of traditional hotel sheets with that smooth, matte finish. They don’t feel fuzzy or plush. The structure provides a clean, professional impression.

Sateen weaves in commercial grades offer more softness. The weaving technique creates a subtle sheen. This approximates luxury without sacrificing too much durability. We recommend sateen for four-star and five-star properties.

Home linens often use jersey knits or brushed finishes. These feel incredibly soft initially. They’re like wearing your favorite t-shirt. But this softness comes from looser weaves and surface treatments that don’t survive industrial laundering.

Color and Design Constraints

White dominates commercial hospitality for practical reasons I mentioned earlier. But color options are expanding.

Why Hotels Stick With White:

- Universal appeal across demographics

- Easy stain detection during sorting

- Allows bleach for deep sanitization

- Never goes out of style

- Shows cleanliness clearly to guests

Some boutique hotels now use colors. We’ve supplied gray, ivory, and even navy linens. These require careful laundering to prevent fading. Color-safe bleach alternatives cost more. Whites remain most economical.

Aesthetic Customization Options

Home buyers have unlimited design choices. Florals, stripes, geometric patterns, seasonal themes. Retail stores stock hundreds of options.

Commercial buyers get customization differently:

Available Commercial Customizations:

- Embroidered logos or monograms

- Custom hemstitching colors

- Jacquard-woven patterns

- Striped or checkered borders

- Dobby weave textures

We can create custom designs for large orders (usually 500+ pieces). Smaller hotels should stick with standard options to maintain cost efficiency.

The Luxury Paradox

Here’s something that surprises people: extremely soft doesn’t always mean better quality.

Super-soft home linens often achieve that feel through:

- Silicone fabric softeners

- Brushing that loosens fibers

- Very loose weaves

- Thin, weak yarns

These techniques create immediate softness but accelerate breakdown. The linens pill, tear, and lose absorbency quickly.

Quality commercial linens feel firm initially but improve with use. The tight weave and strong fibers maintain integrity while gradually softening through natural fiber breakdown.

What Common Myths Should You Stop Believing?

Misconceptions cost buyers thousands in poor decisions. Let me correct the most damaging myths we encounter.

The biggest myths include: commercial linens always feel rough (quality commercial bedding can be quite soft), higher thread count means better quality (weave construction matters more), home linens last as long with care (construction differences are fundamental), and white linens are boring (professional appearance appeals to most guests). These myths lead buyers toward poor purchasing decisions based on marketing rather than performance data.

Myth 1: Thread Count Determines Quality

I’ve already touched on this, but it deserves emphasis.

Thread count became a marketing arms race. Brands advertise 1,000+ thread counts. Physical reality makes this nearly impossible with single-ply yarns in standard weaving.

Manufacturers use tricks:

- Multi-ply yarns counted as separate threads

- Thinner, weaker fibers packed tightly

- Loose weaves that feel soft initially

We’ve tested 600-thread-count retail sheets against our 200-thread-count commercial percale. Our commercial version lasted 4x longer. The retail sheets felt softer initially but pilled and tore quickly.

Focus on GSM (fabric weight) and weave type instead. A 160 GSM percale sheet with 200 thread count outperforms a 100 GSM sheet with 400 thread count every time.

Myth 2: Commercial Always Feels Rough

This was true 20 years ago. Modern commercial linens have evolved significantly.

The roughness people remember came from 100% polyester hotel sheets in budget properties. Those days are gone. Current polycotton blends with 60%+ cotton content feel quite comfortable.

Our luxury commercial line uses 80/20 cotton-polyester blends. Guests consistently rate these sheets 4.5+ stars for comfort. They maintain this softness through hundreds of washes.

The key is trying modern commercial products, not judging based on old experiences.

Myth 3: Home Linens With Care Last Just As Long

Careful home laundering helps, but it can’t overcome fundamental construction differences.

Home linens use:

- Lighter weight fabrics (90-130 GSM vs 155-180 GSM)

- Single-stitched or standard hemming

- Yarns optimized for softness over strength

- Weaves with lower pick counts

No amount of gentle washing changes these structural limitations. You might extend life from 50 to 80 washes. Commercial linens still reach 250-400 washes.

Myth 4: All Commercial Linens Are The Same

Quality varies dramatically in commercial products. Not all suppliers maintain the same standards.

Quality Indicators to Check:

- GSM weight (verify specifications)

- Stitch density at hems

- Selvage edge quality

- Actual fiber content (request lab tests)

- Manufacturer certifications

We’ve tested competitor products claiming "hotel quality" that weighed only 120 GSM. That’s barely heavier than retail home linens. Real commercial sheets should hit 155+ GSM minimum.

Always request physical samples before large orders. Touch and examine the construction yourself.

Conclusion

Commercial linens deliver superior durability and cost-efficiency for high-volume settings. Home linens provide immediate comfort and aesthetic variety for personal use. Choose based on your usage frequency and priorities.

-

Learn how GSM (grams per square meter) measurement determines fabric density, durability, and suitability for different textile applications, with detailed explanations of weight ranges for commercial versus home use. ↩

-

Discover why polycotton blends (60/40 or 70/30 cotton-polyester) provide the optimal balance of comfort, durability, and cost-effectiveness for hospitality settings, lasting up to 4x longer than pure cotton alternatives. ↩

-

Understand the complete commercial laundering process including specific temperature requirements (140-170°F), chemical formulations, wash cycle steps, and how industrial systems differ fundamentally from home washing machines. ↩

-

Explore why thread count can be misleading in determining linen quality and why GSM (fabric weight) provides a more accurate, manipulation-proof measurement of durability and performance, especially for commercial textiles. ↩

-

Learn how Airbnb and short-term rental hosts select hospitality-grade linens designed to withstand 100+ washings (60% more than retail), with best practices for inventory management, laundering, and cost optimization. ↩

-

Compare the two most popular hotel sheet weaves: percale’s crisp, cool, breathable feel versus sateen’s smooth, silky texture, including their durability characteristics, maintenance requirements, and ideal applications in hospitality. ↩