Hotels across the industry face a common challenge: balancing guest expectations for luxury linens with operational costs that continue to rise. Towel complaints, frequent replacements, and climbing laundry expenses add up quickly. For many properties, the solution lies in understanding what microfiber actually is and how it performs in hospitality environments.

Microfiber is a synthetic fiber finer than 1 denier1 (10 micrometers in diameter), typically made from 80% polyester and 20% polyamide blends. Hotels use it for towels, bathrobes, and cleaning cloths because it absorbs up to seven times its weight in water, lasts 500+ washes, and can reduce annual linen costs by 40-60% compared to cotton alternatives.

This guide covers the technical specifications that matter for hotel purchasing decisions, realistic cost comparisons, and care protocols that maximize product lifespan.

What Exactly Is Microfiber and Why Do Hotels Use It?

Understanding microfiber starts with its definition. The term describes any synthetic fiber measuring less than one denier in thickness—about 1/100th the diameter of a human hair. Manufacturers produce it by extruding molten polyester and nylon through fine nozzles, creating ultra-thin filaments that are then woven or knit into fabric.

Microfiber’s performance advantages come from its construction. Hotels choose it because the material maintains absorbency and appearance through hundreds of commercial laundry cycles, requires less frequent replacement than cotton, and dries faster—reducing both energy costs and turnaround time.

How Manufacturing Affects Performance

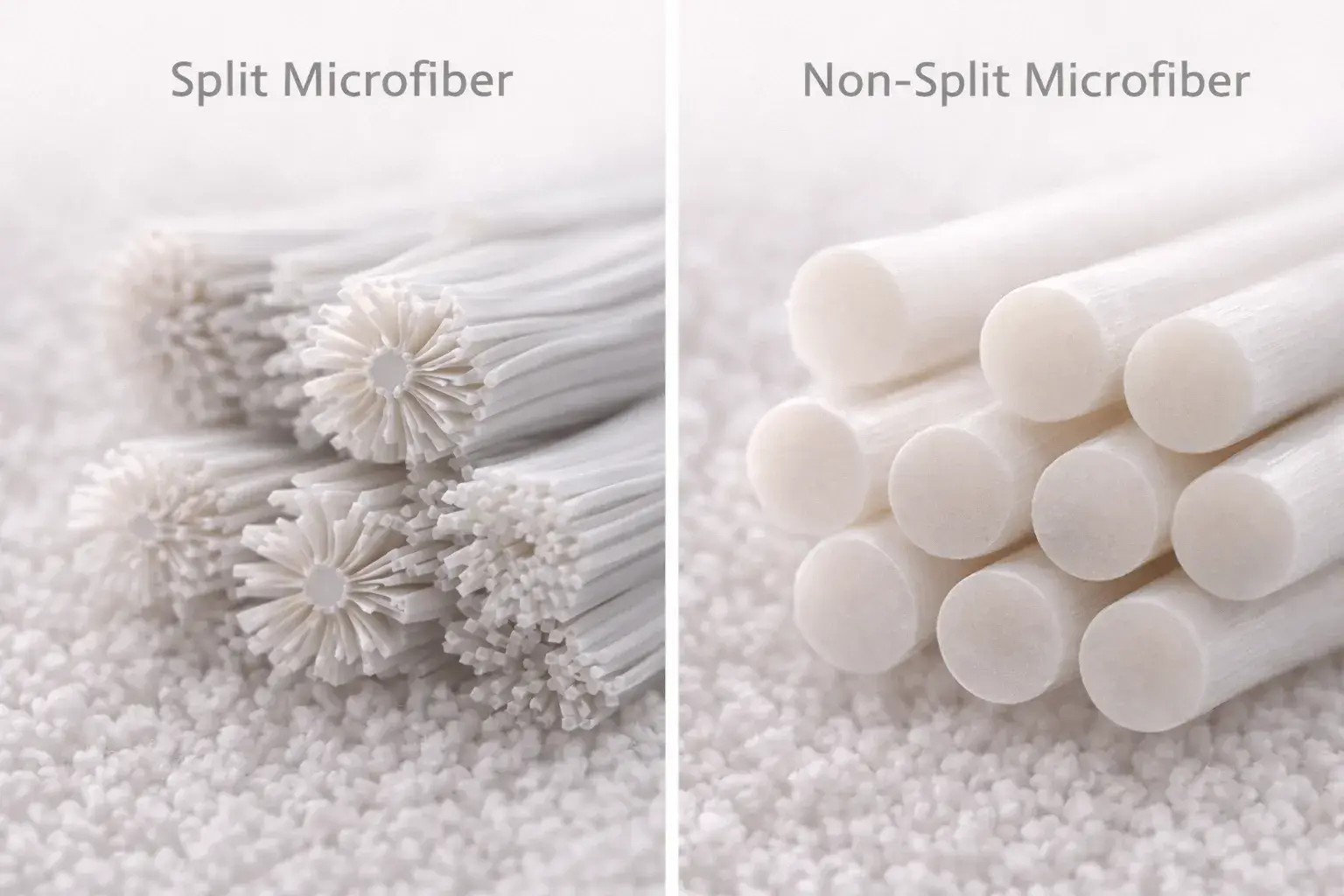

The production process directly impacts quality. After extrusion, manufacturers "split" the filaments during dyeing, breaking each strand into multiple smaller fibers. This creates a star-shaped cross-section with increased surface area.

Split microfiber absorbs water more effectively than non-split versions. The microscopic channels between split fibers pull in moisture through capillary action, which is why quality microfiber towels dry guests faster than similarly weighted cotton towels.

Non-split microfiber feels soft but lacks absorbency. It’s often used in apparel rather than towels. For hotel applications, split microfiber is essential.

Understanding GSM Ratings for Hotel Towels

GSM (grams per square meter2) indicates fabric density. Higher numbers mean thicker, more absorbent towels—but also higher costs and longer drying times.

| GSM Range | Hotel Application | Typical Lifespan | Considerations |

|---|---|---|---|

| 200-250 | Pool towels, gym facilities | 200-300 washes | Lightweight, quick-drying |

| 300-350 | Standard guest bath towels | 350-450 washes | Balanced performance |

| 400-500+ | Luxury properties, spa towels | 500+ washes | Premium feel, longer dry time |

Most mid-tier hotels find 300-350 GSM provides the best balance of guest satisfaction and operational efficiency. Luxury properties often specify 450+ GSM for the premium hand-feel guests expect.

The Polyester-Nylon Blend Matters

Standard microfiber contains approximately 80% polyester and 20% polyamide (nylon). Each component serves a purpose:

- Polyester provides structure and durability

- Nylon enhances absorbency and softness

Budget suppliers sometimes reduce nylon content below 15% to cut costs. This compromises absorbency and creates towels that feel rougher against skin. When reviewing supplier specifications, verify the blend ratio in writing.

How Is Microfiber Made and What Makes Hotel-Grade Different?

Not all microfiber meets commercial hospitality standards. Consumer-grade products designed for home use typically fail within 50-100 washes in hotel laundry operations. Hotel-grade microfiber must withstand harsher conditions.

Hotel-grade microfiber requires GSM ratings above 300, tight weave construction (minimum 200 threads per inch), and reinforced edges. It must survive repeated laundering at 140-160°F with commercial detergents while maintaining absorbency and appearance.

The Splitting Process

After weaving, manufacturers submerge fabric in chemical baths that partially dissolve the fiber surface. This controlled process splits each filament into 8-16 smaller strands. The result resembles an asterisk in cross-section.

Proper splitting creates the absorbent channels that make microfiber effective. Insufficient splitting produces fabric that looks like microfiber but performs poorly—water beads on the surface rather than absorbing.

Common Quality Shortcuts

Three manufacturing shortcuts reduce product lifespan in hotel environments:

Incomplete fiber splitting: Rushed or skipped splitting processes reduce absorbency by 40-60%. The fabric may pass visual inspection but fails performance testing.

Low nylon content: Reducing nylon below 15% cuts raw material costs but produces scratchy, less absorbent towels. Some budget suppliers use as little as 5% nylon.

Loose weave construction: Thread counts below 150 per inch create fabric that pills quickly and develops surface roughness within 100 washes. Hotel-grade should specify 200+ threads per inch.

Specifications to Request from Suppliers

Before placing orders, request documentation for:

- GSM rating (verified by independent testing, not just manufacturer claims)

- Polyester/nylon blend ratio (preferably 80/20 or 85/15)

- Thread count per square inch

- Wash durability testing results (should document 500+ cycles)

- Edge construction method (double-stitched hems prevent fraying)

Reputable suppliers provide this information readily. Hesitation or vague responses indicate potential quality issues.

Microfiber vs. Cotton in Hotels: Which Delivers Better ROI?

The cotton-versus-microfiber decision involves multiple factors beyond initial purchase price. Total cost of ownership3 includes replacement frequency, laundry energy consumption, and guest satisfaction impact.

When accounting for the complete ownership cycle, quality microfiber typically costs 40-60% less annually than cotton for most hotel applications. A 100-room property can expect to save $8,000-12,000 per year by switching to appropriate microfiber products.

Three-Year Cost Projection

Consider a 100-room hotel at 70% occupancy requiring 800 bath towels in rotation:

Cotton Towels:

- Initial investment: 800 × $12 = $9,600

- Year 2 replacement (50%): $4,800

- Year 3 replacement (50%): $4,800

- Additional laundry energy (25% longer drying): $3,600

- Total: $22,800

Quality Microfiber (300+ GSM):

- Initial investment: 800 × $15 = $12,000

- Year 2 replacement (10-15%): $1,500

- Year 3 replacement (10-15%): $1,500

- Standard laundry energy: Baseline

- Total: $15,000

Net savings over three years: $7,800

These figures assume proper care protocols for both materials. Improper laundering significantly reduces microfiber lifespan.

Guest Perception Data

Industry surveys comparing cotton and microfiber in hotel settings show mixed results depending on property tier:

Mid-tier properties (3-star): Guests rate microfiber towels slightly higher (4.3/5 vs 4.1/5) due to faster drying and maintained softness through repeated use.

Luxury properties (4-5 star): Cotton maintains an advantage (4.5/5 vs 3.9/5) in perceived quality, even when microfiber performs better functionally. Guest expectations play a significant role.

Absorbency and performance: Microfiber consistently outperforms cotton in objective measurements—water absorption, drying speed, and durability.

When Cotton Remains the Better Choice

Microfiber doesn’t suit every property. Cotton makes more sense for:

- Luxury brand positioning: Properties marketing "Egyptian cotton" as a signature amenity should maintain consistency with guest expectations

- Hot, humid climates: Cotton breathes better, which matters for comfort in tropical locations

- Strong sustainability messaging: Despite microfiber’s longer lifespan, some eco-focused brands prioritize natural, biodegradable materials

For standard 3-4 star properties in temperate climates focused on operational efficiency, microfiber typically delivers better overall value.

What Are the Hidden Costs of Low-Quality Microfiber in Hotels?

Price differences between suppliers can be substantial. Budget microfiber at $8 per towel looks attractive compared to quality products at $15. However, the apparent savings often reverse quickly.

Low-quality microfiber generates three categories of hidden costs: increased guest complaints requiring staff intervention and compensation, accelerated replacement cycles (150 washes vs 500 washes), and potential reputation damage that affects repeat booking rates.

Guest Complaint Management Costs

Each linen complaint requires multiple staff touchpoints:

- Housekeeping supervisor response

- Front desk intervention

- Replacement delivery

- Manager follow-up

- Potential compensation (room credits or loyalty points)

Industry benchmarks suggest these interactions cost $35-50 per incident when accounting for labor and compensation. Properties using substandard microfiber report 3-4x more linen complaints than those using quality products.

Replacement Cycle Economics

Budget microfiber (200-250 GSM, loose weave) typically requires replacement after 150-200 commercial wash cycles. Quality microfiber (300+ GSM, proper construction) lasts 450-500 cycles.

For a 100-room hotel washing towels daily:

- Budget microfiber needs replacement every 10-12 months

- Quality microfiber needs replacement every 30-36 months

Over three years, the budget option requires purchasing 2,400 towels (three complete replacements). The quality option requires 1,000 towels (one purchase plus 20% ongoing replacement).

At scale, the quality product costs less despite a 50-80% higher unit price.

Quality Warning Signs

Monitor these indicators during the first 60-90 days of any new microfiber purchase:

- Visible pilling after fewer than 50 washes indicates loose weave construction

- Color fading suggests low-quality dyes or insufficient fiber splitting

- Reduced absorbency where water beads on the surface shows manufacturing defects

- Edge fraying before 100 washes points to poor hem construction

- Guest comments about towel quality, even infrequent ones, signal problems

Two or more warning signs within the first 60 days typically predict premature product failure.

How Should Hotels Care for Microfiber to Maximize Lifespan?

Standard cotton laundry protocols damage microfiber. The material requires different handling to maintain performance through its expected 500+ wash lifespan.

Microfiber performs best with warm water washing4 (maximum 140°F), pH-neutral detergents, and low-heat drying. Using standard cotton protocols—hot water, fabric softeners, high-heat drying—reduces microfiber lifespan by 60% or more.

Six Common Laundry Mistakes

Hotels frequently damage microfiber through practices that work fine for cotton:

1. Fabric softener use

Softeners coat the split fibers, filling the microscopic channels that provide absorbency. After 10-15 washes with softener, water absorption drops by 50-60%. Avoid all fabric softeners with microfiber.

2. Washing with cotton items

Cotton sheds lint that becomes trapped deep in microfiber’s split structure. This can’t be removed through standard washing. Always launder microfiber separately from cotton linens.

3. High-temperature drying

Heat above 140°F begins melting polyester fibers. The damage accumulates over time—50 high-heat cycles can reduce absorbency by 40%. Use low heat or air drying.

4. Chlorine bleach

Bleach degrades polyester molecular bonds, causing premature breakdown. Use oxygen-based alternatives for stain treatment.

5. Overloading washers

Microfiber needs space to agitate freely. Fill commercial washers to 70% capacity maximum.

6. Direct heat pressing

Irons and steam presses melt polyester instantly. While hotels rarely iron towels, some press bathrobes—this destroys microfiber absorbency immediately.

Recommended Commercial Laundry Protocol

Washing:

- Water temperature: 100-140°F (warm, not hot)

- Detergent: pH-neutral formula without additives

- Load size: 70% capacity maximum

- Cycle: Normal wash with cold rinse

- Frequency: After each guest checkout

Drying:

- Temperature: Low heat (120-130°F) or air dry

- Duration: Remove when dry; avoid over-drying

- Additives: None

Stain Treatment:

- Oxygen bleach or enzyme cleaners

- Maximum 30-minute pre-soak

- Never use chlorine bleach

Staff Training Essentials

Changing laundry protocols requires clear communication with housekeeping teams. Effective training includes:

- Visual demonstrations showing the difference between properly maintained and damaged microfiber

- Written protocols posted in laundry areas

- Weekly spot checks during the first month to ensure compliance

- Monthly brief reminders to prevent backsliding to cotton protocols

The key message: microfiber is different from cotton and requires different care. Most staff adapt quickly once they understand why the protocols differ.

Is Microfiber Sustainable Enough for Eco-Conscious Hotel Brands?

Sustainability considerations involve multiple factors. Microfiber presents both environmental challenges and advantages compared to cotton.

Microfiber’s primary environmental concern is microplastic pollution5—each wash cycle releases hundreds of thousands of synthetic fibers into wastewater. However, microfiber requires 60% less water to manufacture than cotton, lasts three times longer, and consumes 25% less laundry energy. The net environmental impact depends on mitigation strategies.

Understanding Microplastic Shedding

Every time microfiber goes through a wash cycle, friction causes tiny plastic fibers to break off. These fibers measure less than 5mm and flow through most wastewater treatment plants into rivers, lakes, and oceans.

Research indicates synthetic textiles contribute approximately 35% of microplastics found in marine environments. A hotel washing 200 microfiber towels daily releases an estimated 140 million microfibers monthly into the water system.

These fibers don’t biodegrade. They accumulate in aquatic ecosystems, are consumed by marine life, and enter the food chain. Long-term health impacts remain under study.

Three Practical Mitigation Strategies

Hotels can significantly reduce microplastic pollution:

Strategy 1: Commercial laundry filters

External washing machine filters6 capture 80-90% of shed microfibers before they enter wastewater. Installation costs $500-800 per commercial machine. Filters require cleaning every 10-20 wash cycles.

For a 100-room hotel with three commercial washers: $2,100 installation plus approximately $400 annually in maintenance labor. This prevents roughly 1.1-1.3 billion microfibers from entering waterways yearly.

Strategy 2: Laundry bags

Mesh bags like Guppyfriend contain microfiber items during washing and trap approximately 65-70% of shed fibers. Cost: $30-35 per bag. Less effective than machine filters but useful for properties where filter installation isn’t feasible.

Strategy 3: Recycled microfiber

Specifying microfiber made from recycled PET bottles (post-consumer plastic) doesn’t prevent shedding but diverts plastic waste from landfills. Recycled microfiber reduces manufacturing emissions by 25-30% compared to virgin polyester.

Expect a 10-15% price premium over standard microfiber.

Full Lifecycle Environmental Comparison

Manufacturing phase:

Cotton requires 15,000-20,000 liters of water per kilogram of fiber. Microfiber uses approximately 2,000 liters (90% reduction). Cotton farming involves significant pesticide and fertilizer use. Microfiber production generates petrochemical emissions.

Use phase:

Cotton towels require 20-25% more energy to dry due to higher water retention. Over 500 washes, this equals 150-180 kWh additional energy per towel. Microfiber sheds plastic fibers with each wash. Cotton doesn’t.

End-of-life:

Cotton biodegrades in 1-5 months under proper conditions. Microfiber persists 200+ years in landfills. Neither material is commonly recycled through existing textile recycling systems.

Net assessment:

Microfiber’s longer lifespan (500 vs 200 washes) reduces overall manufacturing impact by approximately 60%. When combined with commercial laundry filters capturing 80-90% of shed fibers, microfiber can achieve better total lifecycle environmental performance than cotton for most hotel applications.

Communicating Sustainability Choices to Guests

Eco-conscious guests may ask about synthetic textiles. Transparent communication works better than avoiding the topic:

"We use high-quality microfiber towels because they last three times longer than cotton, reducing manufacturing waste. To address microplastic concerns, we’ve installed commercial laundry filters that capture 90% of shed fibers. Our microfiber contains 30% recycled content from post-consumer plastic bottles. We believe this approach delivers the best overall environmental outcome."

This response demonstrates informed decision-making rather than hiding behind marketing language.

Conclusion

Microfiber delivers measurable operational advantages for hotels: 40-60% lower annual costs, 500+ wash durability, and strong guest satisfaction scores when quality standards are met. Success requires purchasing 300+ GSM products with verified specifications, implementing proper laundry protocols, and addressing environmental concerns through filtration systems. For most properties, these factors combine to make microfiber the superior choice for towels and bathrobes.

-

Wikipedia: Microfiber – Comprehensive technical overview of microfiber definition, history, and manufacturing processes. ↩

-

Understanding GSM in Towels – Detailed explanation of GSM ratings and their impact on towel quality and performance. ↩

-

OEM vs Standard Hotel Towels Cost Comparison – Industry cost analysis comparing microfiber and cotton towels across hotel segments. ↩

-

How to Wash Microfiber – Commercial Care Instructions – Professional laundry protocols for maintaining microfiber products in commercial settings. ↩

-

Microplastic Shedding from Laundry – Research on microfiber pollution from washing and emerging mitigation technologies. ↩

-

PlanetCare Microfiber Filters – Commercial washing machine filter solutions capturing 90%+ of microplastic fibers. ↩