Hotel linens make or break guest satisfaction. Scratchy sheets and thin towels generate complaints daily. The right materials deliver comfort, survive 500+ washes, and fit your budget.

Hotels use cotton (Egyptian, Pima, Supima), cotton-polyester blends (60/40 ratio), linen, bamboo, and microfiber for linens. Long-staple cotton offers premium softness and durability. Blends provide wrinkle resistance at lower costs. Fiber length and weave quality matter more than thread count alone.

Choosing the right materials saves money on replacements while keeping guests happy. Let’s break down what actually works in real hotel operations.

What Makes Hotel Linens So Comfortable and Durable?

Bedding quality shows up consistently in guest reviews. The secret lies in fiber science and construction methods that most suppliers don’t explain clearly.

Hotel linens combine long-staple natural fibers with tight weaves to create breathability and resilience. Long-staple cotton fibers (over 1.5 inches) resist pilling through 200-500 wash cycles. Percale and sateen weaves balance airflow with smoothness for year-round comfort.

The Science Behind Comfort

Comfort comes from three factors working together.

Fiber length determines softness. Long-staple fibers1 create smooth surfaces without rough nubs. These fibers measure 1.5 to 2 inches long. Short-staple cotton barely reaches 1 inch. The difference is obvious after 50 washes.

Moisture management keeps guests dry. Natural fibers absorb up to 20% of their weight in water without feeling damp. Linen performs best here. Cotton comes in second place.

Breathability prevents overheating. Percale weave allows maximum airflow. Each thread crosses over-and-under in a simple pattern. This creates tiny gaps for ventilation. Guests sleep cooler on percale compared to tighter weaves.

Durability Factors That Matter

Construction quality determines lifespan more than price. Here’s what we’ve learned from supplying hundreds of properties.

Long-staple fibers last significantly longer than short-staple varieties. The longer strands create fewer weak points where fabric tears. Short-staple linens typically need replacement every 12-18 months. Long-staple options often survive 24-36 months of heavy use.

Weave density affects lifespan. Higher thread count doesn’t always mean better quality. Some 800-thread-count sheets pill faster than 300-count options. The secret is single-ply construction with quality fibers.

Industrial washing destroys weak linens quickly. Hotels use water temperatures around 60°C (140°F) with strong detergents. Only well-constructed fabrics survive this treatment repeatedly.

| Durability Factor | Impact on Lifespan | What to Look For |

|---|---|---|

| Fiber length | 2-3x longer life | Over 1.5 inches (long-staple) |

| Ply construction | 50% better durability | Single-ply preferred |

| Weave quality | Resists pilling | Tight, even pattern |

| Finishing treatment | 20-30% life extension | Mercerized or sanforized |

Why Hotel Beds Feel Different

Guests ask this question constantly. Hotel beds feel amazing because properties layer quality materials strategically.

We typically start with fitted sheets in percale weave. The crisp texture stays cool all night. Top sheets use the same material for consistency. Duvet covers might be sateen for a smoother hand feel.

Regular replacement schedules make a huge difference. Hotels rotate linens every 2-3 months. Fresh fabric simply feels better than year-old sheets at home.

Professional laundering also matters. Commercial equipment removes oils and dead skin completely. Home washers leave residue that stiffens fabric over time.

Common Materials Used in Hotel Bed Sheets and Towels

Material choice determines operational costs for years. These aren’t theoretical recommendations. We’ve supplied millions of dollars worth of linens and seen what actually performs.

Hotels primarily use cotton (60%), cotton-polyester blends (30%), and alternative materials like linen or bamboo (10%) for sheets. Towels rely on Turkish or Egyptian cotton at 500-700 GSM (grams per square meter). Microfiber appears in budget properties for quick-drying benefits.

Bed Sheet Materials Breakdown

Cotton dominates the sheet market for good reasons. It breathes naturally and feels soft against skin. But not all cotton performs equally.

Egyptian cotton comes from Nile Delta plants with extra-long fibers. These sheets cost $100-200 per set wholesale. They last 300-400 industrial washes before showing wear. Luxury properties favor this material for premium rooms.

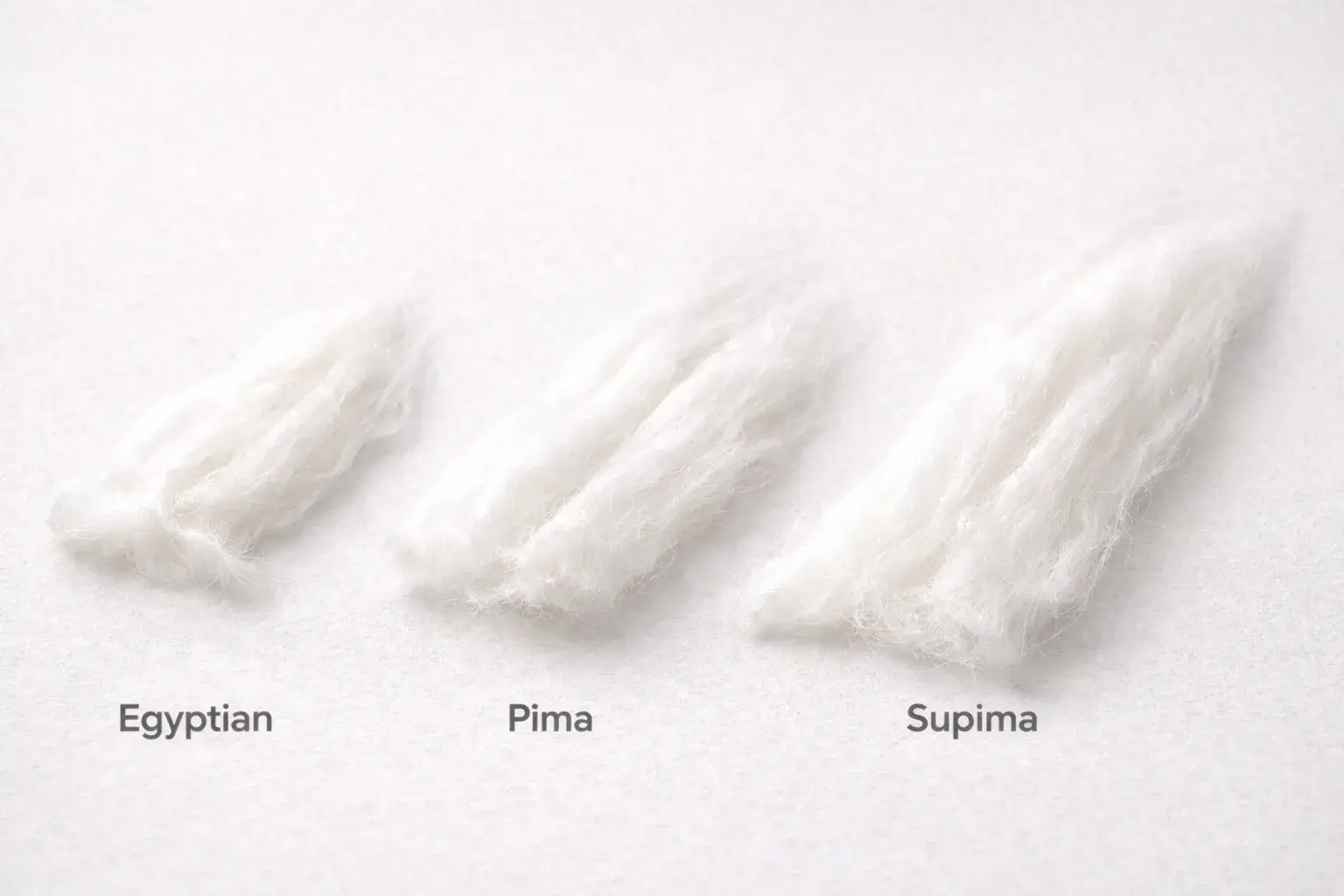

Pima and Supima cotton grow in the United States and Peru. The fiber length matches Egyptian cotton quality. Prices run $70-150 per set. Many properties can’t distinguish between Supima and Egyptian in blind comparisons. The "Supima" trademark guarantees American origin.

Regular cotton uses shorter fibers. Sheets cost $30-60 per set. They work fine for budget hotels. Expect replacement after 150-200 washes. The fabric pills more quickly than long-staple options.

Cotton-polyester blends mix 60% cotton with 40% synthetic fiber. This combination resists wrinkles dramatically. Housekeeping saves 15-20 minutes per room on ironing. Wholesale cost sits at $25-50 per set.

Towel Material Standards

Towels need different properties than sheets. Absorbency matters most. We measure this in GSM ratings.

Turkish cotton creates highly absorbent towels. The long loops soak up water efficiently. Luxury spas use Turkish cotton almost exclusively. Bath towels should hit 600-700 GSM2. Hand towels work well at 400-500 GSM.

Egyptian cotton towels feel softer initially. But Turkish cotton improves with washing. After 50 wash cycles, Turkish towels often outperform Egyptian options in absorbency tests.

Microfiber towels dry in half the time. Budget hotels appreciate this feature. Laundry costs drop when towels spend less time in dryers. The synthetic texture bothers some guests though.

| Material Type | Best Use | Wholesale Cost/Set | Expected Wash Cycles |

|---|---|---|---|

| Egyptian cotton | Luxury sheets | $100-200 | 300-400 |

| Pima/Supima | Premium sheets | $70-150 | 300-400 |

| Regular cotton | Budget sheets | $30-60 | 150-200 |

| 60/40 blend | Mid-tier sheets | $25-50 | 200-300 |

| Turkish cotton | Premium towels | $15-30/towel | 400-500 |

| Microfiber | Budget towels | $5-12/towel | 250-300 |

Table Linen Considerations

Table linens face unique challenges. Food stains attack fabric aggressively. Bleach treatments wear down pure cotton quickly.

Cotton-linen blends work well for tablecloths. The linen content adds natural stain resistance. These fabrics cost more upfront ($40-80 per cloth). They typically last 50% longer than pure cotton options.

Polyester napkins work perfectly for casual dining. They resist staining and rarely need replacement. White polyester napkins cost $2-4 each. Cotton napkins run $3-6 but stain permanently after heavy use.

Restaurant linens should always be white. Stain removal works better on white fabric. Colored linens hide stains temporarily but look dingy within months. White looks fresh or shows problems immediately.

Pros and Cons of Cotton, Blends, and Alternative Fabrics

Every material involves trade-offs. Understanding real-world advantages and problems helps you match materials to your specific property needs.

Pure cotton offers superior breathability and hypoallergenic properties but shrinks 3-5% and costs more. Blends provide wrinkle resistance and durability for 30% less money but breathe poorly and pill over time. Alternative materials like linen resist bacteria naturally but wrinkle excessively and feel coarse initially.

Pure Cotton Advantages and Drawbacks

Cotton feels amazing against skin. Quality cotton sheets generate very few guest complaints. The natural fiber regulates temperature automatically.

Cotton advantages:

- Breathability keeps guests comfortable in all seasons

- Hypoallergenic properties reduce skin irritation complaints

- Softness improves with washing (up to 50 cycles)

- Easy to bleach for stain removal without damage

- Absorbs moisture naturally without feeling clammy

Cotton challenges:

- Shrinkage reaches 3-5% even with preshrunk treatments

- Wrinkles form quickly and require ironing labor

- Higher wholesale costs ($50-200 per sheet set)

- Stains set permanently without immediate treatment

- Wear becomes visible after 200-300 washes in high-turnover properties

Cotton makes sense for luxury hotels where guest experience trumps costs. Budget properties struggle with the price point and maintenance requirements.

Cotton-Polyester Blend Performance

Blends changed the hotel industry starting in the 1990s. Housekeeping efficiency jumped dramatically. Many properties use blends in 40% or more of their rooms.

Why blends work well:

- Wrinkle resistance cuts ironing time by 60-70%

- Lower costs ($25-50 per set) improve profit margins

- Durability extends lifespan to 200-300 industrial washes

- Color retention beats pure cotton significantly

- Less shrinkage (under 2%) simplifies inventory management

Where blends fall short:

- Reduced breathability causes overheating complaints

- Pilling appears after 100 washes on lower-quality blends

- Synthetic feel bothers luxury hotel guests

- Cannot withstand bleach as effectively as pure cotton

- Environmental concerns from non-biodegradable polyester

A 60/40 cotton-polyester ratio works well for mid-tier hotels. This balances comfort and practicality. Avoid 50/50 blends. They feel too synthetic.

Alternative Fabric Reality Check

Marketing hype surrounds bamboo and linen materials. Testing reveals mixed results worth understanding.

Linen (flax-based) characteristics:

- Natural antimicrobial properties reduce bacteria growth

- Excellent breathability (better than cotton)

- Durability can outlast cotton by 20-30%

- Cost runs similar to premium cotton ($80-180 per set)

- Wrinkles constantly and looks rumpled within hours

- Feels coarse for first 20-30 washes

- Works well for European properties where wrinkled linen signals authenticity

Bamboo fabric realities:

- Silky soft texture rivals luxury cotton

- Sustainable growing process uses significantly less water than cotton

- Naturally temperature-regulating for hot climates

- Manufacturing requires harsh chemical processing

- Durability falls short of quality cotton

- Costs $60-120 per set wholesale

- Guest acceptance remains mixed

Microfiber practical uses:

- Extremely affordable ($20-40 per sheet set)

- Quick-drying reduces laundry energy costs

- Stain-resistant surface simplifies cleaning

- Synthetic feel generates complaints in rooms over $150/night

- Static buildup annoys guests

- Best suited for budget properties under $80/night

| Material | Best Property Type | Key Advantage | Major Drawback | Typical Guest Response |

|---|---|---|---|---|

| Pure cotton | Luxury (4-5 star) | Breathability | High cost | Very positive |

| 60/40 blend | Mid-tier (3 star) | Low maintenance | Reduced breathability | Generally positive |

| Linen | Boutique/European | Antimicrobial | Wrinkles badly | Mixed reviews |

| Bamboo | Eco-focused | Sustainability | Chemical processing | Mixed reviews |

| Microfiber | Budget (2 star) | Affordability | Synthetic feel | Acceptable at low rates |

Material Selection Framework

A simple decision tree helps with purchasing. Start with your average daily rate (ADR).

Properties over $200 ADR: Use pure long-staple cotton exclusively. Guest expectations demand this quality level. The higher cost becomes negligible compared to room rates.

Properties $100-200 ADR: Mix materials strategically. Use cotton for sheets and pillowcases. Use blends for duvet covers where direct skin contact is minimal. This saves roughly 20% on linen costs while maintaining comfort.

Properties under $100 ADR: Choose blends for everything except towels. Guests prioritize cleanliness over luxury at this price point. Save money on sheets and invest in decent towels instead.

Climate matters significantly. Tropical properties benefit from bamboo in regions averaging over 25°C (77°F). The cooling effect can justify the cost. Cold-climate properties benefit from sateen cotton that retains warmth better.

Which Cotton Types Do Hotels Actually Use?

Cotton quality varies dramatically. Misleading labels fool even experienced buyers. Here’s what separates premium from mediocre cotton linens.

Luxury hotels use Egyptian, Pima, or Supima cotton with fiber lengths exceeding 1.5 inches. Mid-tier properties choose Upland cotton with shorter fibers. Budget hotels often use generic cotton without origin certification. Fiber length impacts durability significantly more than thread count.

Egyptian Cotton Reality Check

Egyptian cotton is the most overhyped material in hospitality. Yes, authentic Egyptian cotton performs beautifully. But genuine Egyptian cotton is rare in the marketplace.

True Egyptian cotton grows in the Nile River Valley. The long growing season produces extra-long staple (ELS) fibers measuring 1.5-2 inches. These fibers create incredibly smooth, durable fabric.

Here’s the problem: many sheets labeled "Egyptian cotton" don’t contain authentic Egyptian fibers. Testing has shown that budget-priced "Egyptian" linens often perform worse than basic American cotton. The label means nothing without proper certification.

Look for GIZA certification on authentic Egyptian cotton. GIZA 45, 87, and 88 are the premium grades. These cost $150-250 per sheet set wholesale. Anything priced under $100 probably isn’t real Egyptian cotton.

Many properties now use Supima cotton for standard rooms. It performs identically to Egyptian cotton at 40% lower cost. Egyptian cotton gets reserved for presidential suites where the prestigious name matters.

Pima and Supima Cotton Benefits

Pima cotton grows primarily in the southwestern United States, Peru, and Australia. The fiber length matches Egyptian cotton at 1.5+ inches. This creates the same smooth, durable fabric.

Supima is trademarked Pima cotton3 grown exclusively in the USA. The Supima association guarantees American origin and quality standards. This trademark provides reliable quality assurance.

Pima cotton costs $70-120 per sheet set wholesale. Supima runs $90-150. The performance matches or exceeds Egyptian cotton. Many hotels now use Supima in 70-80% of their luxury rooms.

The fabric softens beautifully after 20-30 washes. Guests often ask which brand properties use. Durability reaches 350-400 industrial wash cycles before replacement. This exceeds regular cotton by 100-150 cycles.

Turkish Cotton for Towels

Turkish cotton deserves special mention. While Egyptian and Pima work best for sheets, Turkish cotton dominates towel quality.

The secret lies in the longer fiber loops. Turkish cotton creates fluffier, more absorbent towels. After washing hands, Turkish towels dry completely in one wipe. Egyptian towels often need multiple wipes.

Turkish towels improve with age. The loops open up after 50-100 washes. Absorbency actually increases during the first year. Egyptian towels peak immediately and decline slowly.

Quality Turkish cotton bath towels cost $18-30 each. This runs double compared to regular cotton towels at $9-15. The investment typically pays back through longer lifespan and fewer guest complaints.

Upland Cotton (The Standard Option)

Upland cotton accounts for roughly 90% of global cotton production. This is what most hotels actually use. The fiber length measures 1-1.25 inches. It’s not premium but works fine for budget properties.

Upland cotton sheets cost $30-60 per set wholesale. They feel decent when new. After 50-100 washes, the fabric gets rougher. Pills form on the surface. Durability maxes out around 150-200 wash cycles.

Upland cotton suits properties under $80 per night. Guests at this price point rarely comment on sheet quality unless there’s an obvious problem. They care more about cleanliness and value. Upland cotton delivers acceptable quality at budget-friendly prices.

Organic Cotton Considerations

Organic cotton uses no pesticides or synthetic fertilizers. The environmental benefits are measurable. Water usage drops significantly compared to conventional cotton. Performance varies though.

Organic certification doesn’t guarantee fiber length. Some organic sheets use short-staple fibers that perform poorly. Look for GOTS (Global Organic Textile Standard) certification4 plus long-staple designation.

Quality organic cotton costs $100-180 per set. This matches premium conventional cotton prices. The eco-appeal attracts environmentally conscious guests.

Organic cotton works well in boutique properties marketing environmental responsibility. The sustainability story can boost review ratings. For standard hotels, conventional long-staple cotton often offers better value.

| Cotton Type | Fiber Length | Wholesale Cost/Set | Best For | Expected Lifespan |

|---|---|---|---|---|

| GIZA Egyptian | 1.5-2 inches | $150-250 | Presidential suites | 350-400 washes |

| Supima | 1.5+ inches | $90-150 | Luxury rooms | 350-400 washes |

| Pima | 1.5+ inches | $70-120 | Premium rooms | 300-350 washes |

| Turkish (towels) | 1.4-1.6 inches | $18-30/towel | All towel needs | 400-500 washes |

| Organic long-staple | 1.3-1.6 inches | $100-180 | Eco-properties | 300-350 washes |

| Upland | 1-1.25 inches | $30-60 | Budget rooms | 150-200 washes |

How to Verify Cotton Quality

Labels lie constantly. Verify cotton quality through simple tests before bulk ordering.

Request samples and wash them 10 times at hotel-standard temperatures (60°C/140°F). Quality cotton gets softer. Poor cotton gets rougher and pills.

Check the fiber ends with a magnifying glass. Long-staple cotton shows minimal loose fiber ends. Short-staple cotton looks fuzzy and messy.

Ask for fiber length certification from the supplier. Legitimate vendors provide third-party lab results. Less reliable suppliers make excuses or provide vague answers.

Test absorbency for towels. Pour 50ml of water on a dry towel. Time how long absorption takes. Quality Turkish cotton absorbs in under 3 seconds. Mediocre cotton takes 5-8 seconds or longer.

These verification methods prevent expensive mistakes. Trust your testing over marketing claims every time.

What About Alternative Materials Like Linen, Bamboo, and Microfiber?

Cotton dominates but alternatives serve specific purposes. We’ve deployed these materials strategically across different property types. Each solves particular problems that cotton cannot address as effectively.

Linen offers natural antimicrobial properties and superior breathability compared to cotton, ideal for warm climates and European boutique hotels. Bamboo provides sustainable softness for eco-conscious properties but requires chemical processing. Microfiber delivers budget-friendly quick-drying benefits for hostels and economy hotels despite synthetic texture.

Linen Fabric Advantages

Linen comes from flax plants. This material dominated bedding before cotton became cheap and abundant. Now it’s making a comeback in upscale properties.

Linen’s natural properties stand out. The fabric resists bacteria growth significantly better than cotton. This matters for hot, humid locations where bacteria multiply quickly. Guests report fewer skin irritations with linen sheets.

Breathability exceeds cotton noticeably. Air flows through linen’s loose weave structure effortlessly. Rooms without air conditioning benefit enormously. Some historic European properties use linen exclusively where modern HVAC would damage architecture.

Durability surprises most buyers. Linen can last 20-30% longer than equivalent cotton. The flax fibers are hollow, creating natural flexibility. Fabric doesn’t break down under stress as quickly. Well-maintained linen tablecloths can survive 7-8 years of weekly washing.

The wrinkle problem is very real. Linen wrinkles dramatically. Housekeepers spend considerably more time making beds with linen sheets. Some properties embrace the rumpled look as "authentically European luxury." American properties often struggle with this aesthetic.

Cost sits at $80-180 per sheet set. This matches premium cotton pricing. For boutique hotels marketing natural luxury, linen creates the right atmosphere.

Bamboo Fabric Truth

Bamboo bedding generates intense marketing hype. The sustainability story appeals to eco-conscious travelers. Manufacturing reality is more complicated than marketing suggests.

Bamboo grows incredibly fast without pesticides or irrigation. The plant regenerates from roots after harvesting. This makes bamboo farming much more water-efficient than cotton. The environmental story holds up at the growing stage.

Processing bamboo into fabric requires harsh chemicals. Manufacturers dissolve bamboo cellulose in sodium hydroxide and carbon disulfide. The resulting rayon fabric is soft but not exactly "natural" anymore. Look for closed-loop processing certifications where the vast majority of chemicals get recycled.

The fabric feels silky smooth. Bamboo sheets regulate temperature well in hot climates. The fabric wicks moisture better than cotton.

Durability falls short though. Bamboo sheets last 200-250 washes before pilling badly. Quality cotton exceeds this by 100+ washes. The lower lifespan offsets some cost savings.

Bamboo works in specific situations:

- Eco-boutique hotels marketing sustainability (despite processing concerns)

- Budget properties in hot climates where cooling matters more than longevity

- Spa environments where silky texture enhances relaxation experience

Wholesale cost runs $60-120 per set. This sits between budget cotton and premium long-staple varieties.

Microfiber Performance Reality

Microfiber means polyester fibers thinner than 1 denier. This creates soft, tightly-woven synthetic fabric. Budget hotels discovered microfiber about 15 years ago. Adoption grew rapidly in economy segments.

Microfiber advantages:

- Extremely affordable at $20-40 per sheet set

- Dries much faster than cotton, cutting laundry energy costs

- Stain resistance beats cotton on common spills

- Wrinkle-resistant fabric needs minimal ironing

- Durability reaches 250-300 washes before deterioration

Guest complaints about microfiber:

- Synthetic texture feels "plasticky" to many guests

- Poor breathability causes overheating

- Static buildup attracts lint and hair

- Not eco-friendly (petroleum-based, non-biodegradable)

- Pills badly after 150 washes despite durability claims

Microfiber works best in properties under $75 per night. Guest expectations align with the synthetic feel at this price point. Above $100 per night, microfiber generates complaints quickly.

One exception: Microfiber towels work brilliantly for pool and gym use. The quick-drying property prevents mildew smell. Guests expect athletic towels to feel different from bath towels. Switching pool towels to microfiber eliminates most mildew issues.

Tencel and Eucalyptus Fabrics

Tencel (lyocell) comes from eucalyptus wood pulp. This newer material combines sustainability with performance. Testing over the last few years shows promise.

The closed-loop manufacturing process recovers 99% of solvents. This makes Tencel highly environmentally friendly. Eucalyptus trees grow quickly on non-arable land without irrigation.

Tencel performance characteristics:

- Silky soft texture rivals bamboo

- Moisture-wicking ability exceeds cotton significantly

- Natural antimicrobial properties reduce bacteria

- Hypoallergenic qualities perfect for allergy-prone guests

- Wrinkle resistance better than cotton but not as good as blends

Cost runs $90-160 per sheet set. This positions Tencel as a premium alternative. It works well in boutique properties targeting environmentally conscious travelers aged 25-45.

Guest satisfaction tends to be positive overall. Some guests still prefer traditional cotton familiarity. Durability hits 280-320 washes before replacement. This falls short of quality cotton but beats bamboo and microfiber.

Climate-Based Material Selection

Location determines which alternative materials work best. Expensive mistakes teach these lessons quickly.

Hot, humid climates (Florida, Southeast Asia, Middle East summer):

- Primary: Bamboo or Tencel for moisture-wicking

- Secondary: Linen for breathability

- Avoid: Microfiber (traps heat and moisture)

Hot, dry climates (Southwest USA, Mediterranean):

- Primary: Linen for cooling airflow

- Secondary: Bamboo for softness

- Avoid: Heavy cotton blends

Temperate climates (Most of USA, Europe):

- Primary: Quality cotton (still the best all-rounder)

- Secondary: Tencel for eco-marketing

- Budget option: Microfiber acceptable

Cold climates (Northern Europe, Canada):

- Primary: Sateen cotton (warmth retention)

- Secondary: Cotton blends

- Avoid: Linen (too cool), microfiber (guests associate cold weather with natural warmth)

| Alternative Material | Best Climate | Cost/Set | Lifespan (Washes) | Key Benefit | Major Limitation |

|---|---|---|---|---|---|

| Linen | Hot/humid | $80-180 | 300-400 | Antimicrobial, breathable | Wrinkles excessively |

| Bamboo rayon | Tropical | $60-120 | 200-250 | Moisture-wicking | Chemical processing |

| Microfiber | Any (budget) | $20-40 | 250-300 | Quick-drying, affordable | Synthetic feel |

| Tencel/Lyocell | Warm | $90-160 | 280-320 | Eco-friendly, soft | Higher cost |

When Alternatives Make Financial Sense

Cost-benefit analysis helps with every material choice. Alternatives work when they solve specific operational problems.

Use linen when: Historic property aesthetics demand natural materials, or antimicrobial properties help reduce illness complaints in high-occupancy situations.

Use bamboo when: Eco-certifications demonstrably boost booking rates, or tropical climate causes excessive cotton replacement from mildew.

Use microfiber when: Operating margins are razor-thin under $65 ADR, or quick turnover demands fast laundry processing.

Use Tencel when: Target demographic prioritizes sustainability over traditional luxury, or allergy complaints appear frequently in guest feedback.

Cotton remains the default choice for most applications. Alternatives need clear operational or marketing justification. Don’t chase trends. Choose materials that solve actual problems for your specific property.

How Thread Count and Weave Impact Linen Quality

Thread count obsession wastes money. Some 200-count sheets outlast 800-count options. Weave pattern and fiber quality matter far more than numbers on labels.

Thread count between 200-400 with single-ply long-staple cotton delivers optimal hotel quality. Higher counts often use multi-ply tricks that reduce breathability and durability. Percale weave offers crisp coolness5 while sateen provides silky warmth. For towels, GSM (grams per square meter) at 600-700 determines absorbency better than thread count.

Thread Count Marketing Myths

Thread count measures threads per square inch of fabric. Simple concept. But manufacturers game this number constantly.

The multi-ply trick: Companies twist 3-4 thin threads together and count each strand separately. A "1000-thread-count" sheet might actually have 250 threads per inch using 4-ply yarn. This creates heavy, stiff fabric that traps heat.

Testing shows that sheets over 600 count rarely perform well in hotel conditions. They:

- Pill faster than 300-400 count alternatives

- Feel heavy and warm (guests complain about overheating)

- Cost 50-100% more without quality improvement

- Wear out faster under industrial washing

Single-ply 300-400 thread count beats multi-ply 600+ consistently. The individual threads are thicker and stronger. Fabric breathes naturally. Durability exceeds inflated-count competitors by significant margins.

Percale Weave Characteristics

Percale uses a simple one-over-one weave pattern. Each thread alternates over and under perpendicular threads. This creates a tight, crisp fabric.

Percale appears in roughly 70% of hotel properties for good reasons:

Temperature regulation: Percale breathes better than sateen weave. Tiny gaps in the over-under pattern allow airflow. Guests sleep cooler on percale sheets.

Durability: The tight weave resists pilling and tearing. Percale sheets survive 300-400 industrial washes before showing wear. Looser weaves fail at 200-250 cycles.

Crisp feel: Percale has a matte finish with slight texture. This feels "hotel-like" to most guests. The crisp hand improves with washing.

Cost efficiency: Percale requires less processing than sateen. Wholesale prices run 15-20% lower for equivalent quality.

Percale works perfectly in warm climates or properties without strong air conditioning. Switching from sateen to percale in Florida properties can significantly reduce cooling complaints.

The main drawback is wrinkling. Percale wrinkles more than sateen or blends. Housekeeping time increases for pressing. Factor this labor cost into your decision.

Sateen Weave Performance

Sateen uses three-over-one weave. Three threads pass over one perpendicular thread. This creates a smooth, lustrous surface.

Luxury hotels love sateen’s silky appearance. The fabric catches light beautifully. Guests perceive sateen as higher quality even when fiber content is identical to percale.

Sateen advantages:

- Wrinkle resistance reduces ironing time considerably

- Soft hand feel appeals to most guests in blind tests

- Shiny finish looks expensive and luxurious

- Less prone to snagging than percale

Sateen limitations:

- Traps heat (warmer than percale)

- Pills faster under friction (guests tossing at night)

- Costs 15-25% more than percale

- Durability drops to 250-300 washes versus percale’s 300-400

Use sateen strategically. Cold-climate properties benefit from the warmth retention. Luxury suites get sateen for the premium appearance. Standard rooms in warm locations typically get percale for comfort.

GSM for Towels (Not Thread Count)

Towel quality depends on weight, not thread count. We measure this in GSM (grams per square meter). Higher GSM means thicker, more absorbent towels.

GSM guidelines:

- Washcloths: 300-400 GSM

- Hand towels: 400-500 GSM

- Bath towels: 600-700 GSM

- Bath sheets: 700-800 GSM

Below 500 GSM, bath towels feel thin and cheap. Above 800 GSM, they take too long to dry in commercial dryers. Energy costs jump significantly for heavy towels.

Targeting 650 GSM for standard bath towels balances absorbency with drying efficiency. Luxury properties can go to 700-750 GSM for plush appeal.

Loop length matters too. Longer loops (5-7mm) absorb more water. But very long loops snag easily. Specifying 6mm loops provides optimal performance.

Testing Quality Before Bulk Purchase

Never order thousands of sheets based on specifications alone. Test samples through realistic hotel conditions first.

Testing protocol:

- Wash samples 10 times at 60°C (140°F) with hotel-grade detergent

- Dry on commercial equipment (not home dryers)

- Check for pilling, shrinkage, color fading

- Test hand feel after washing (should soften, not roughen)

- Measure actual thread count with magnifying loupe if claimed over 400

Red flags indicating poor quality:

- Pilling appears before 10 washes

- Shrinkage exceeds 3%

- Fabric stiffens instead of softening

- Color fades noticeably

- Actual thread count is significantly below claimed number

Quality sheets improve with the first 20-30 washes. Poor sheets deteriorate immediately. This simple test saves enormous money on bad purchases.

| Weave Type | Best For | Thread Count Range | Feel | Durability (Washes) | Cost Premium |

|---|---|---|---|---|---|

| Percale | Warm climates, breathability | 200-400 | Crisp, cool | 300-400 | Baseline |

| Sateen | Luxury feel, cold climates | 300-600 | Silky, warm | 250-300 | +15-25% |

| Twill | Boutique properties | 250-400 | Textured | 280-320 | +10-20% |

Practical Thread Count Recommendations

Stop chasing high numbers. Follow this simple guide based on property type:

Budget properties ($60-100 ADR): 180-250 thread count percale or 60/40 blend. Focus on durability and easy care over luxury feel.

Mid-tier properties ($100-180 ADR): 280-350 thread count percale or sateen. Single-ply construction mandatory. This hits the sweet spot for guest expectations.

Luxury properties ($180+ ADR): 320-400 thread count sateen with long-staple cotton. Higher counts add minimal value. Invest in fiber quality instead.

Thread count arms races benefit manufacturers, not hoteliers. Buy smart based on actual performance testing.

What Should Hotel Buyers Consider for Different Property Types?

Every property type demands different linen strategies. We work with hotels across budget, mid-tier, and luxury segments. One-size-fits-all approaches waste money and frustrate guests.

Budget hotels prioritize durability and low maintenance with 60/40 blends at $25-50 per set. Mid-tier properties balance comfort and cost using 300-count cotton at $60-100. Luxury hotels demand long-staple cotton at $100-200+ for premium guest experience. Climate, laundry capabilities, and target demographics further refine material selection.

Budget Hotel Linen Strategy (Under $100 ADR)

Budget properties operate on thin margins. Every dollar counts. But cheap linens that fail quickly actually cost more than mid-quality options.

60/40 cotton-polyester blends work well for budget hotels. Wholesale cost hits $25-40 per sheet set. These survive 200-300 industrial washes. Pure cotton at this price point barely reaches 100-150 cycles.

Key purchasing decisions:

- Buy white exclusively. Colored linens look cheap when faded. White signals cleanliness and simplifies bleaching.

- Standard sizes only. Don’t stock California King or specialty sizes unless absolutely necessary. Limit bed types to Queen and Double.

- Towels at 400-500 GSM. Lower quality feels cheap. Higher wastes money on features budget guests don’t value.

Microfiber works for some budget operators. At $20-35 per set, the cost savings are real. Expect more complaints about texture though. Microfiber works best below $75 ADR where guest expectations align with economy positioning.

Maintenance considerations matter enormously. Budget properties rarely have on-site laundry. Commercial laundry services charge per pound. Lighter-weight blends cost less to clean than heavy cotton.

Mid-Tier Property Balance ($100-180 ADR)

Mid-tier hotels face the hardest decisions. Guests expect comfort but won’t pay luxury prices. This strategy has been refined through years of trial and error.

Use 300-350 thread count cotton (Upland or Pima) for sheets. This costs $60-90 per set wholesale. The cotton content delivers comfort. The moderate thread count provides durability.

Material mix approach:

- Fitted and flat sheets: 100% cotton percale (300-count)

- Duvet covers: 60/40 blend (saves money, guests don’t touch directly)

- Pillowcases: 100% cotton (direct face contact matters most)

- Towels: Turkish or Egyptian cotton at 600 GSM

This mixed approach saves roughly 25% compared to all-cotton while maintaining strong guest satisfaction.

Climate adjustments are critical. Florida properties benefit from percale exclusively. Colorado mountain lodges use sateen for warmth. Track complaint patterns monthly and adjust seasonal inventory accordingly.

Mid-tier properties should consider on-site laundry equipment. The capital cost ($50,000-150,000) often pays back within 2-3 years through reduced outsourcing fees and better linen lifespan control.

Luxury Hotel Requirements ($180+ ADR)

Luxury guests notice everything. Cheap linens destroy five-star reputations instantly. Properties have lost full review stars over bedding complaints.

Long-staple cotton is non-negotiable. Choose Supima, Pima, or certified Egyptian cotton. Thread count should sit at 320-400 in percale or sateen weave. Never use blends in guest rooms.

Wholesale cost runs $100-200 per sheet set. Towels cost $20-35 each. This represents 3-5x budget hotel spending. The investment protects your premium positioning.

Luxury linen specifications:

- Fitted sheets: 350-count Supima percale

- Flat sheets: Matching percale or 400-count sateen option

- Duvet covers: 400-count sateen for visual luxury

- Pillowcases: Matching sateen with Oxford edge for elegance

- Towels: 700 GSM Turkish cotton with dobby border

- Bathrobes: 400 GSM velour or terry, 100% cotton

Color strategy for luxury: White remains standard for 90% of linens. High-end properties can use sophisticated neutrals (champagne, slate gray) for differentiation. Test guest response before committing to colored inventory.

Luxury properties should replace linens every 200-250 washes rather than pushing to failure. Slight wear is unacceptable at premium price points. This aggressive replacement schedule costs more but maintains brand standards.

Boutique and Specialty Properties

Boutique hotels sell unique experiences. Linen choices should reinforce your brand story.

Eco-boutique properties: Use GOTS-certified organic cotton or Tencel. Display certifications prominently. Guests paying $150-250 per night at eco-properties expect authentic sustainability. Cost runs $100-180 per set but can justify rate premiums.

Historic properties: Linen (flax) fabric fits period aesthetics. Accept the wrinkled look as authentic charm. Cost sits at $90-170 per set. European travelers especially appreciate this authenticity.

Modern minimalist: Tencel or bamboo in subtle colors (gray, navy, sage). Avoid stark white. Cost runs $80-140 per set. Appeals to design-conscious guests aged 25-40.

Bed & Breakfast operations: Mix textures and patterns more freely. Guests expect personality over standardization. Use quality cotton ($70-120 per set) but don’t obsess over matching sets.

Resort and Extended-Stay Considerations

Resorts face unique linen challenges. Multiple amenity types require specialized purchasing.

Pool and beach towels: Microfiber or low-cost cotton (300-400 GSM). These get lost or damaged constantly. Budget $8-12 per towel and plan for significant annual replacement rates.

Spa towels: Premium Turkish cotton at 650-700 GSM. Spa experiences justify higher cost. Spend $22-30 per towel.

Room towels: Standard 600-650 GSM cotton. Balance quality with volume needs.

Extended-stay properties need more durable options. Guests stay 7-30 days, wearing linens heavily. Commercial-grade blends rated for 400+ washes work well. Cost runs $40-70 per set but prevents frequent replacements.

Calculating Total Cost of Ownership

Purchase price deceives inexperienced buyers. Total cost includes washing, replacement frequency, and labor.

Example calculation for 100-room property:

Budget blend sheets: $35 per set, 250-wash lifespan, 3 sets per room = $10,500 investment

Premium cotton sheets: $85 per set, 350-wash lifespan, 3 sets per room = $25,500 investment

Assuming 300 annual washes per set:

- Budget option: Replace every 10 months = $12,600 annual cost

- Premium option: Replace every 14 months = $21,857 annual cost

Add labor costs for ironing:

- Budget wrinkles badly: Extra time per room = additional annual labor cost

- Premium percale: Minimal extra time = lower annual labor cost

The premium option might cost only 15-20% more annually while delivering significantly better guest experience. This math changes based on your labor costs and wash frequency, but the principle holds: the cheapest linens often cost more long-term.

| Property Type | Recommended Material | Target Thread Count | Cost Per Set | Expected Lifespan |

|---|---|---|---|---|

| Budget (<$100) | 60/40 blend | 180-250 | $25-40 | 200-300 washes |

| Mid-tier ($100-180) | Upland/Pima cotton | 280-350 | $60-90 | 280-350 washes |

| Luxury ($180+) | Supima/Egyptian | 320-400 | $100-200 | 300-400 washes |

| Eco-boutique | Organic/Tencel | 280-350 | $100-180 | 280-320 washes |

| Resort (rooms) | Cotton or blend | 280-350 | $50-90 | 250-320 washes |

| Extended-stay | Commercial blend | 200-300 | $40-70 | 350-400 washes |

Regional and Cultural Preferences

Geography changes guest expectations significantly.

North America: Guests expect substantial, plush towels and crisp sheets. Higher GSM and thread count drive satisfaction. Colored linens are often viewed as budget indicators.

Europe: Guests prefer lighter-weight linens and accept wrinkled linen fabric as luxury. Lower GSM towels (500-600) are standard. Some colored linens signal sophistication.

Middle East: Ultra-luxury standards dominate. Guests expect the absolute best regardless of room rate. White linens are mandatory for cultural cleanliness associations.

Asia: Preferences vary dramatically by region. Japan expects minimalist perfection. China increasingly demands Western-style luxury. Southeast Asia accepts lighter weights due to climate.

Adjust purchasing for properties with significant international clientele. Mixed inventories accommodate different cultural expectations. This adds to inventory costs but prevents cultural disconnect complaints.

How Do You Maintain Hotel-Quality Linens Long-Term?

Proper maintenance doubles linen lifespan. Better laundering protocols can reduce replacement costs by 30-40%. Most properties destroy expensive linens through poor washing practices.

Wash hotel linens in water at 50-60°C (122-140°F)6 with pH-neutral detergent and avoid chlorine bleach. Dry on low heat and remove promptly to minimize wrinkles. Rotate linen inventory every 2-3 months using colored thread markers. Professional laundering with proper equipment extends lifespan significantly compared to improper washing.

Water Temperature and Detergent Selection

Hot water kills bacteria but destroys fabric. Testing across multiple properties reveals clear patterns.

The optimal range is 50-60°C (122-140°F). This temperature sanitizes effectively while minimizing fiber damage. Water above 65°C weakens cotton fibers significantly compared to 55°C washing.

Many operators use 70-80°C (158-176°F) thinking hotter means cleaner. This can cut linen lifespan in half. Your $100 sheets become rags after 150-200 washes instead of 300-350.

Cold water washing (30-40°C) works for lightly soiled linens. Guest rooms with one-night stays rarely need scorching temperatures. Reserve hot washing for heavily soiled items only.

Detergent selection matters enormously. Avoid household brands like Tide or Gain. These contain brighteners and enzymes designed for varied home fabrics. Hotel linens need commercial-grade products.

Alkaline-based commercial detergents with pH 10-11 work well. These break down body oils and protein stains effectively. Cost runs $0.15-0.25 per pound of laundry. Household detergents seem cheaper but perform poorly on hotel soil levels.

Never exceed manufacturer-recommended detergent amounts. Extra soap doesn’t clean better. It leaves residue that stiffens fabric and causes skin irritation. Reducing detergent to proper levels eliminates many "scratchy sheet" complaints.

Bleach and Whitening Strategies

White linens need regular whitening. Chlorine bleach is fabric poison though.

Chlorine bleach weakens cotton fibers significantly per wash cycle. Testing shows bleached linens fail at 180-220 washes. Oxygen-bleached versions reach 320-360 washes.

Use oxygen-based bleach (hydrogen peroxide) instead. This whitens effectively without fiber damage. Cost is comparable to chlorine at $0.08-0.12 per pound of laundry.

Proper whitening protocol:

- Pre-treat stains immediately (before they set)

- Wash with oxygen bleach every 3-4 cycles (not every wash)

- Use chlorine bleach only for heavily stained items you plan to demote to housekeeping rags

- Sort linens by soil level and wash frequency needs

Yellowing happens despite good practices. Replace yellowed linens before guests notice. Dingy white looks worse than obvious wear in guest perception.

Drying Temperature and Technique

Over-drying destroys linens faster than any other factor. Commercial dryers reach 200°C (392°F) in high heat mode. This literally cooks cotton fibers.

Dry on low-medium heat: 60-70°C (140-158°F). This takes 20-30% longer but can double fabric lifespan. The extra energy cost is negligible compared to premature replacement expenses.

Remove linens when slightly damp. They’ll finish drying while folded or hanging. Totally dry linens from high heat become brittle and tear easily.

Over-drying also wastes energy. Stopping dryer cycles 5-10 minutes earlier can cut energy costs significantly. The linens finish air-drying during storage without quality issues.

Rotation and Inventory Management

Most properties don’t rotate inventory properly. Some linens get used 300 times while others sit unused. This creates uneven wear and premature replacement needs.

The par system:

- Par 1: On beds (in guest rooms)

- Par 2: Clean linen storage (ready for use)

- Par 3: In laundry process

- Par 4: Backup inventory for demand spikes

Rotate all pars every 90 days. Mark linens with colored thread by quarter. This ensures even wear across all inventory. Par 4 linens should cycle into regular rotation, not sit unused for years.

Simple colored thread marking system:

- Red thread: Q1 purchase

- Blue thread: Q2 purchase

- Green thread: Q3 purchase

- Yellow thread: Q4 purchase

Rotate colors into and out of service to balance wear. This costs under $50 in supplies and takes minimal time.

Stain Removal Protocols

Fast response prevents permanent stains. Train housekeeping to treat stains immediately upon room checkout.

Common hotel stains and treatments:

- Blood: Cold water and enzyme pre-treatment (within 2 hours)

- Wine: Salt application then cold water rinse (immediate)

- Makeup: Dish soap and warm water (pre-treat before washing)

- Coffee/tea: Boiling water through fabric, then normal wash

- Body oils: Extra detergent in hot water (60°C)

Never send stained linens through regular washing without pre-treatment. The heat sets stains permanently. Dryer heat makes them impossible to remove.

Maintain a stain removal station in every housekeeping area. Cost is under $200 for supplies:

- Enzyme pre-treatment spray

- Oxygen bleach powder

- Spray bottles for solutions

- Soft brushes for scrubbing

- Rubber gloves

- Training poster with stain guide (print yourself)

Professional vs. In-House Laundering

Properties under 75 rooms often outsource laundry. The economics change at scale.

Professional laundry services cost $1.50-3.00 per pound. Average sheet set weighs 4-5 pounds. Each wash costs $6-15 outsourced. Over 300 washes per set lifespan, that’s $1,800-4,500 in washing costs alone.

In-house laundry costs breakdown:

- Equipment investment: $50,000-150,000 (washers, dryers, folders)

- Utility costs: $0.40-0.80 per pound (water, gas, electric)

- Labor costs: $0.60-1.20 per pound (depending on local wages)

- Detergent and chemicals: $0.15-0.25 per pound

- Total: $1.15-2.25 per pound

Break-even typically happens at 75-100 rooms depending on occupancy rates. Above this size, in-house laundry saves 30-40% annually while improving linen lifespan through better control.

Hybrid approach for 50-75 room properties: Wash sheets in-house, outsource towels. Towels require different drying times and equipment. This maximizes in-house efficiency while minimizing equipment investment.

Storage and Handling Best Practices

Poor storage causes yellowing, mildew, and fiber damage without any washing.

Proper storage conditions:

- Temperature: 18-24°C (65-75°F)

- Humidity: 40-60% relative humidity

- Ventilation: Air circulation prevents mustiness

- Darkness: UV light degrades fibers over time

- Organization: First-in-first-out rotation system

Never store linens:

- In plastic bags (traps moisture, causes mildew)

- In direct sunlight (causes yellowing and weakening)

- In damp basements (mildew grows in 48-72 hours)

- Compressed tightly for months (creates permanent creases)

Use wire shelving units for linen storage. The open design allows airflow. Solid shelves trap moisture underneath stacks.

Folding technique affects longevity. Fold along different lines each time. Repeated folding in the same spots weakens fibers. This prevents the common problem of sheets tearing along fold lines.

Tracking and Replacement Schedules

Replace linens on schedule, not by appearance. Waiting for visible wear means guests experienced declining quality for weeks before replacement.

Replacement schedule recommendations:

- Luxury properties: 250 washes or 18 months (whichever comes first)

- Mid-tier properties: 300 washes or 24 months

- Budget properties: 350 washes or 30 months

Track this through simple colored thread quarterly marking for most properties.

Visual inspection every 3 months:

- Check for thinning fabric (hold to light – shouldn’t see through)

- Test for pilling (rough texture)

- Examine stitching integrity

- Verify color consistency

Demote worn linens to housekeeping rags rather than throwing away. This extends value and reduces waste. Never try to extend guest-facing linen life beyond recommended schedules. The cost savings are minimal compared to guest satisfaction risks.

| Maintenance Factor | Best Practice | Cost Impact | Lifespan Impact |

|---|---|---|---|

| Water temperature | 50-60°C (122-140°F) | Baseline | +30% vs. hot washing |

| Bleach type | Oxygen-based only | +$0.04/lb | +40% vs. chlorine |

| Drying heat | Low-medium (60-70°C) | +10% energy | +50% vs. high heat |

| Detergent amount | Per manufacturer specs | Baseline | +15% vs. overuse |

| Rotation frequency | Every 90 days | +5% labor | +25% vs. no rotation |

| Pre-treatment | Immediate stain response | +$0.02/lb | +20% (prevents permanent stains) |

Training Staff for Linen Care

Equipment and protocols mean nothing without proper training.

Monthly training refreshers cover:

- Water temperature and chemical dosing

- Stain identification and pre-treatment

- Proper loading (never overfill washers)

- Drying temperatures and timing

- Folding and storage techniques

- Rotation system compliance

Create visual guides posted at each laundry station. Photos show proper chemical amounts, correct washer loads, and stain treatment steps. Multilingual versions accommodate diverse housekeeping staff.

Track linen replacement costs by property. Properties that extend lifespan beyond average can earn staff recognition. This creates ownership and reduces careless damage.

Poor laundry practices destroy your linen investment faster than guest use. Master these maintenance fundamentals and your linens will serve hundreds of guests successfully.

Conclusion

Match materials to your property type, climate, and guest expectations. Long-staple cotton delivers luxury performance. Blends provide budget-friendly durability. Proper maintenance maximizes every investment.

-

This resource explains the scientific differences between short, long, and extra-long staple cotton fibers, including how fiber length impacts fabric strength, softness, and durability in hotel textiles. ↩

-

This hotel industry guide explains GSM measurement standards for towels, helping buyers understand why 600-700 GSM provides the optimal balance between absorbency, luxury feel, and laundry efficiency. ↩

-

The Supima organization’s official information confirms that Supima is a trademarked certification for 100% American-grown Pima cotton, providing supply chain traceability that protects buyers from counterfeit products. ↩

-

The Global Organic Textile Standard official site details the world’s leading certification for organic textiles, covering environmental and social criteria from farming through manufacturing to ensure authentic organic products. ↩

-

This sleep foundation guide compares percale and sateen weaves scientifically, explaining how the one-over-one-under percale pattern creates cooler, more breathable sheets compared to the three-over-one sateen weave. ↩

-

This hotel laundry industry resource provides professional washing protocols, confirming that 50-60°C water temperature effectively sanitizes linens while preserving fabric integrity better than higher temperatures. ↩